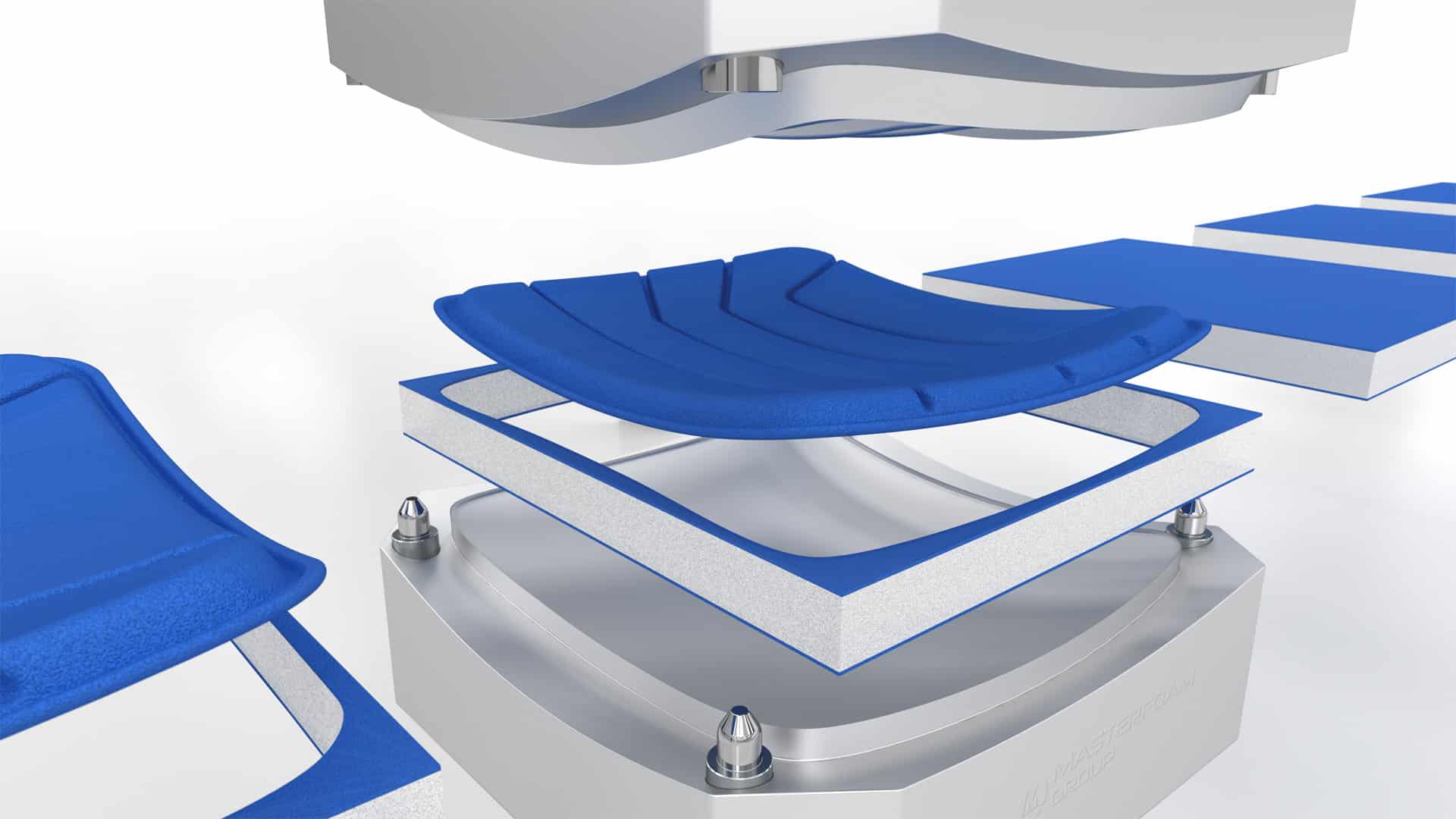

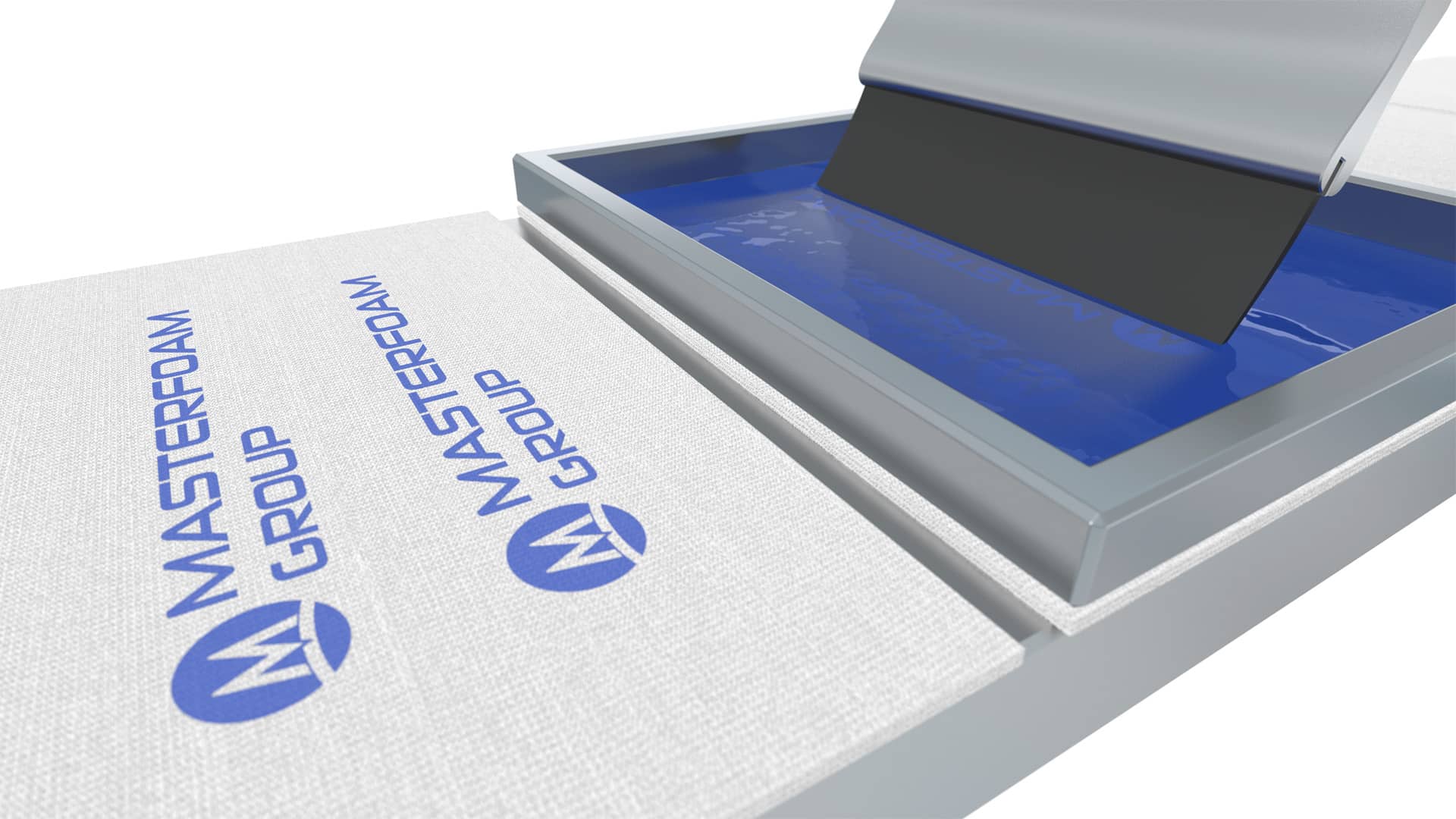

Kiss cutting

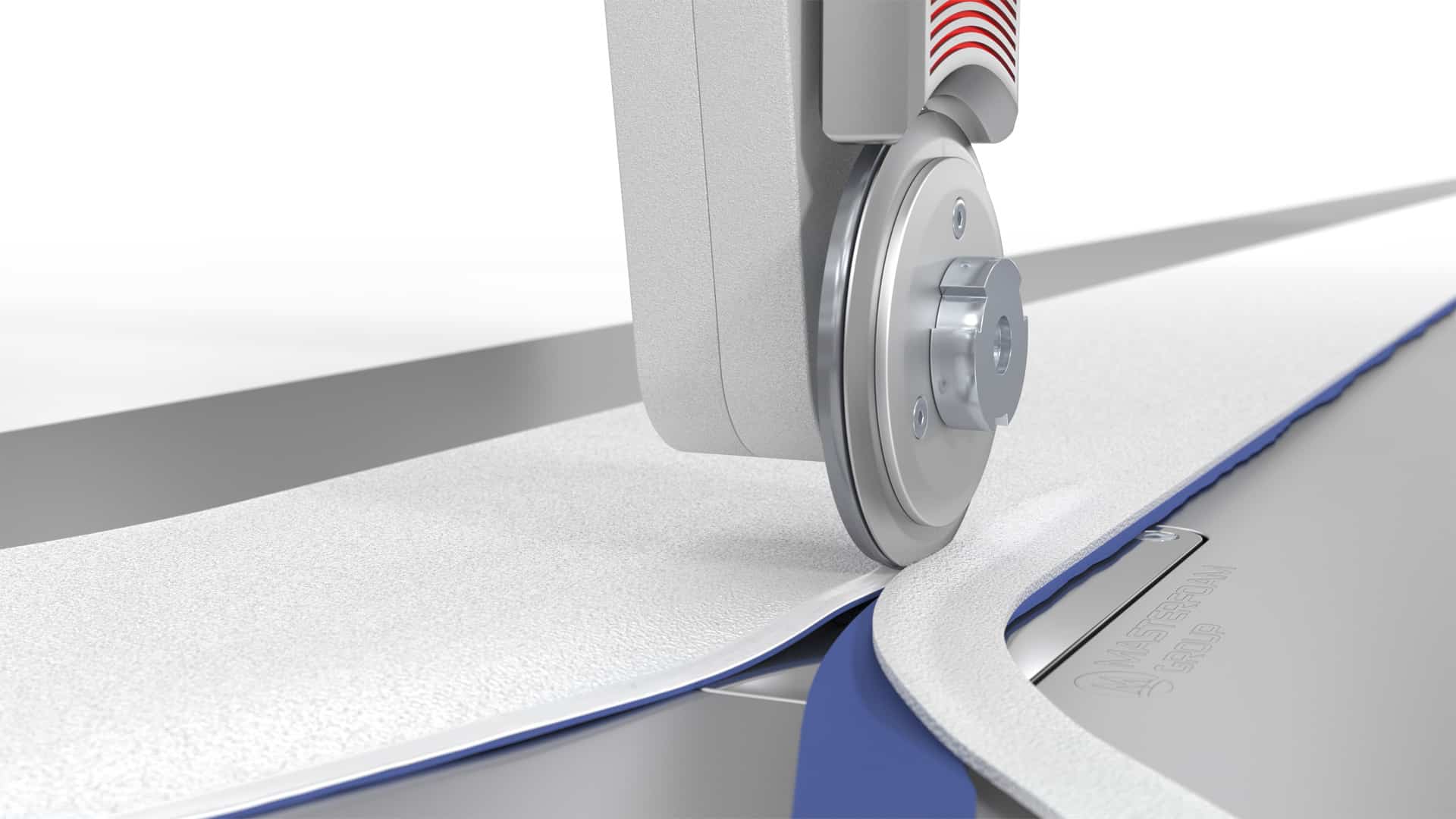

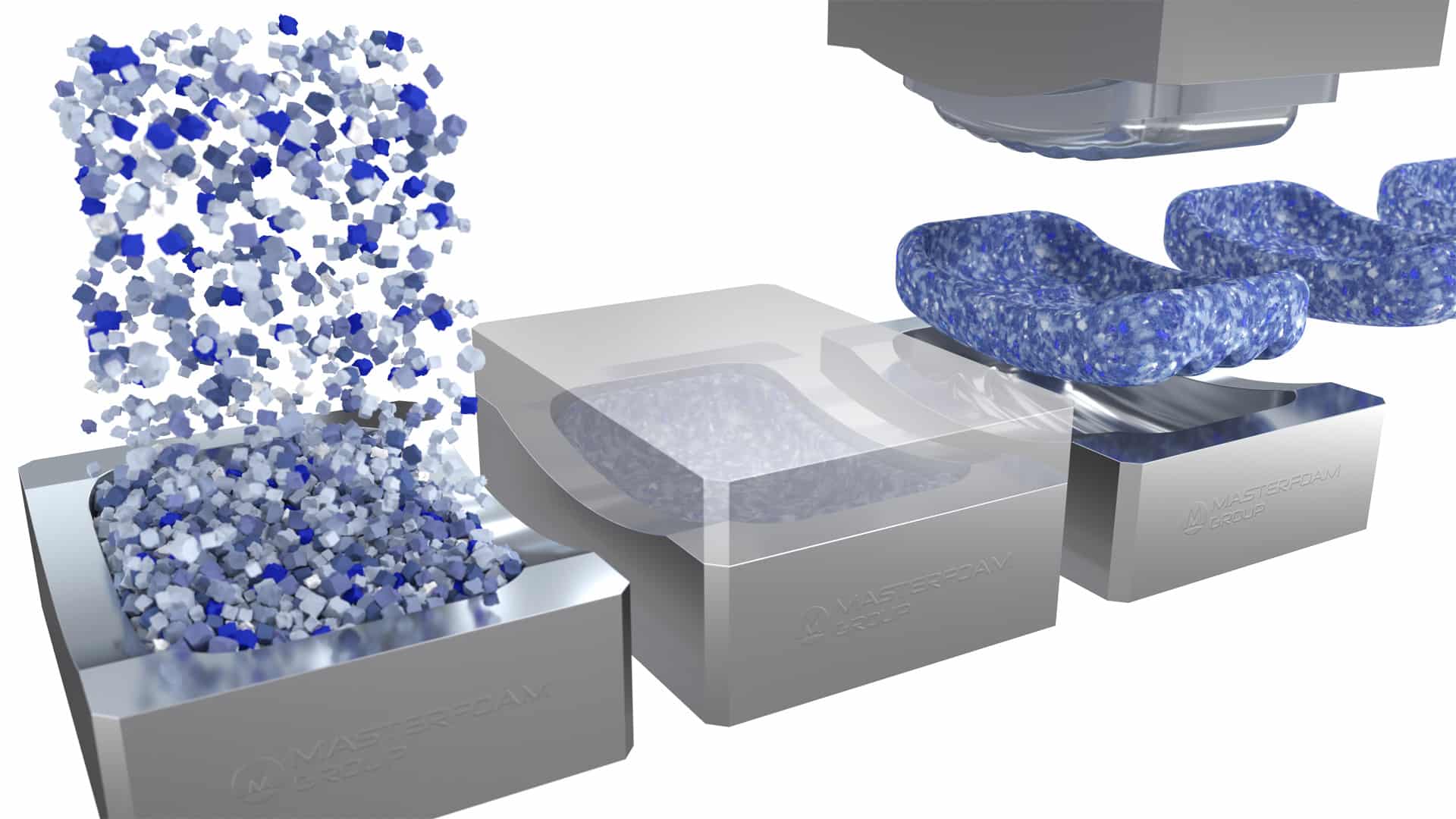

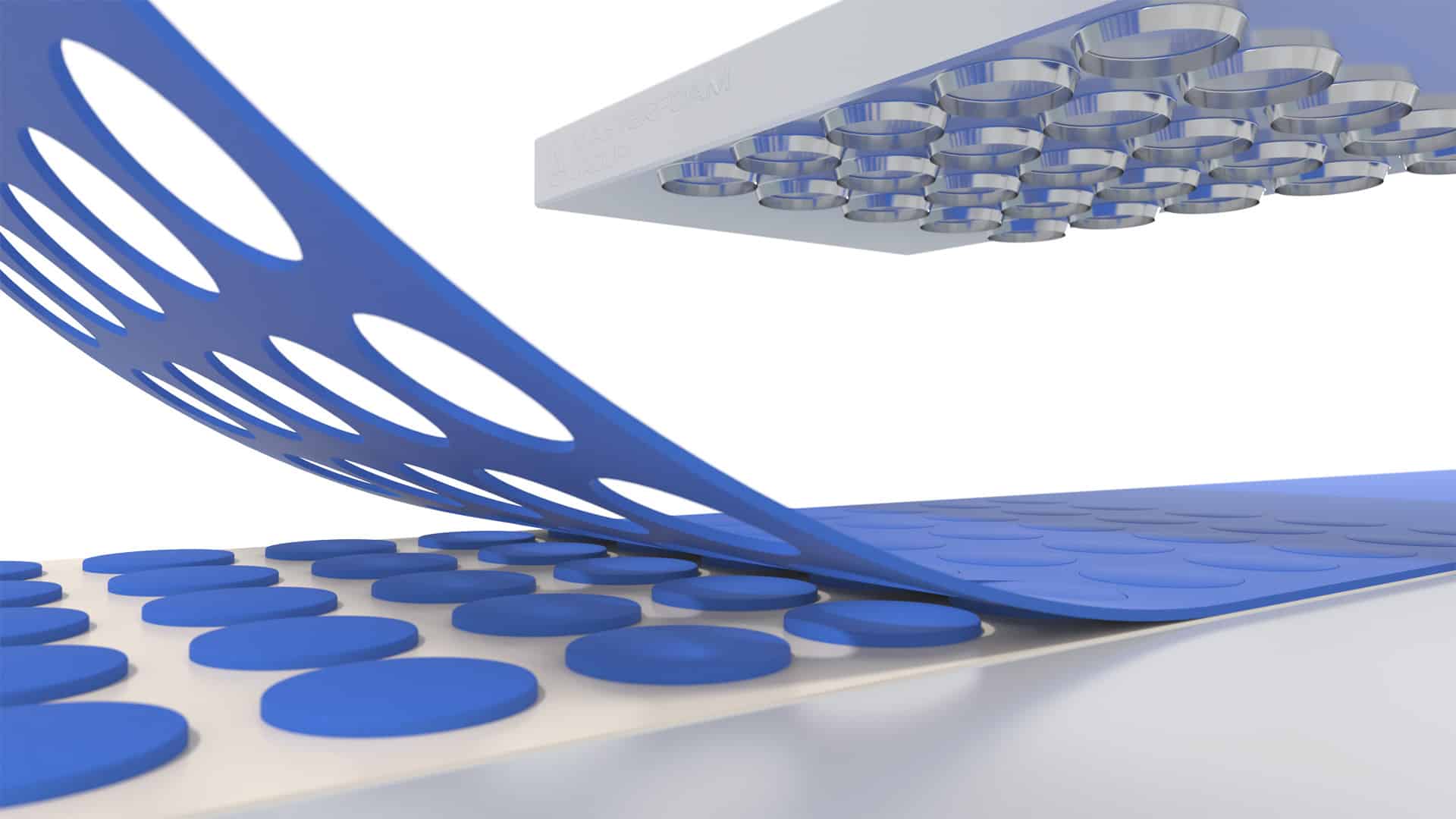

Kiss cutting is the general process of using a diecut knife to proces flexible materials, such as, foam, rubber, felts with an adhesive backing. The precision kisscut techonlogy enables us to cut the flexible material and leave the adhesive backing intact. This results in sheets and rolls with ease to remove parts for assemble on the prodction line.

Benefits

- High output process

- Good option for mid and high volume projects

- Easy removeable parts for assemble

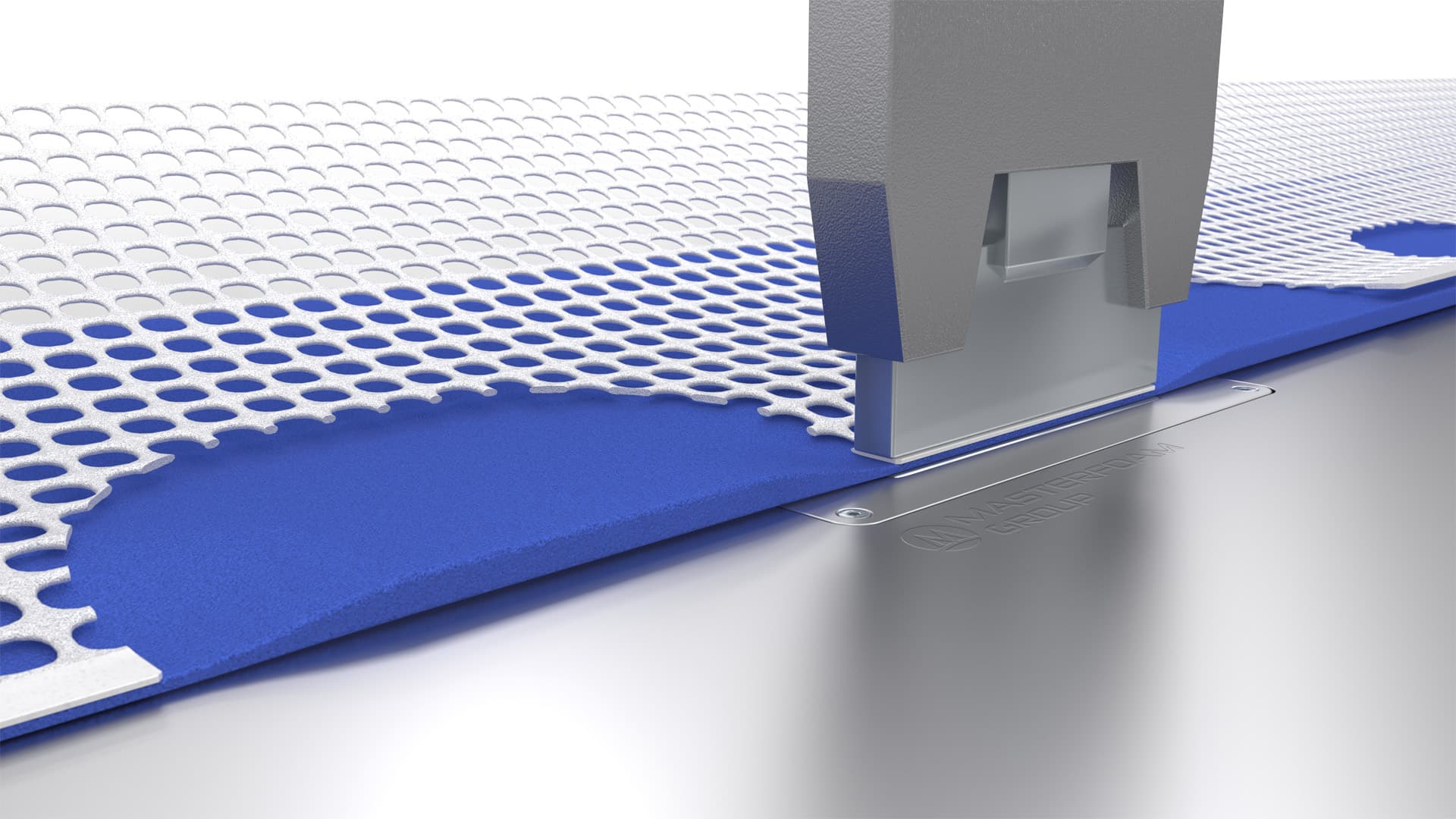

- Works on thin materials while ensuring sharp, precise cuts

- Inexpensive tooling

- Group parts closely on the sheet, reducing waste