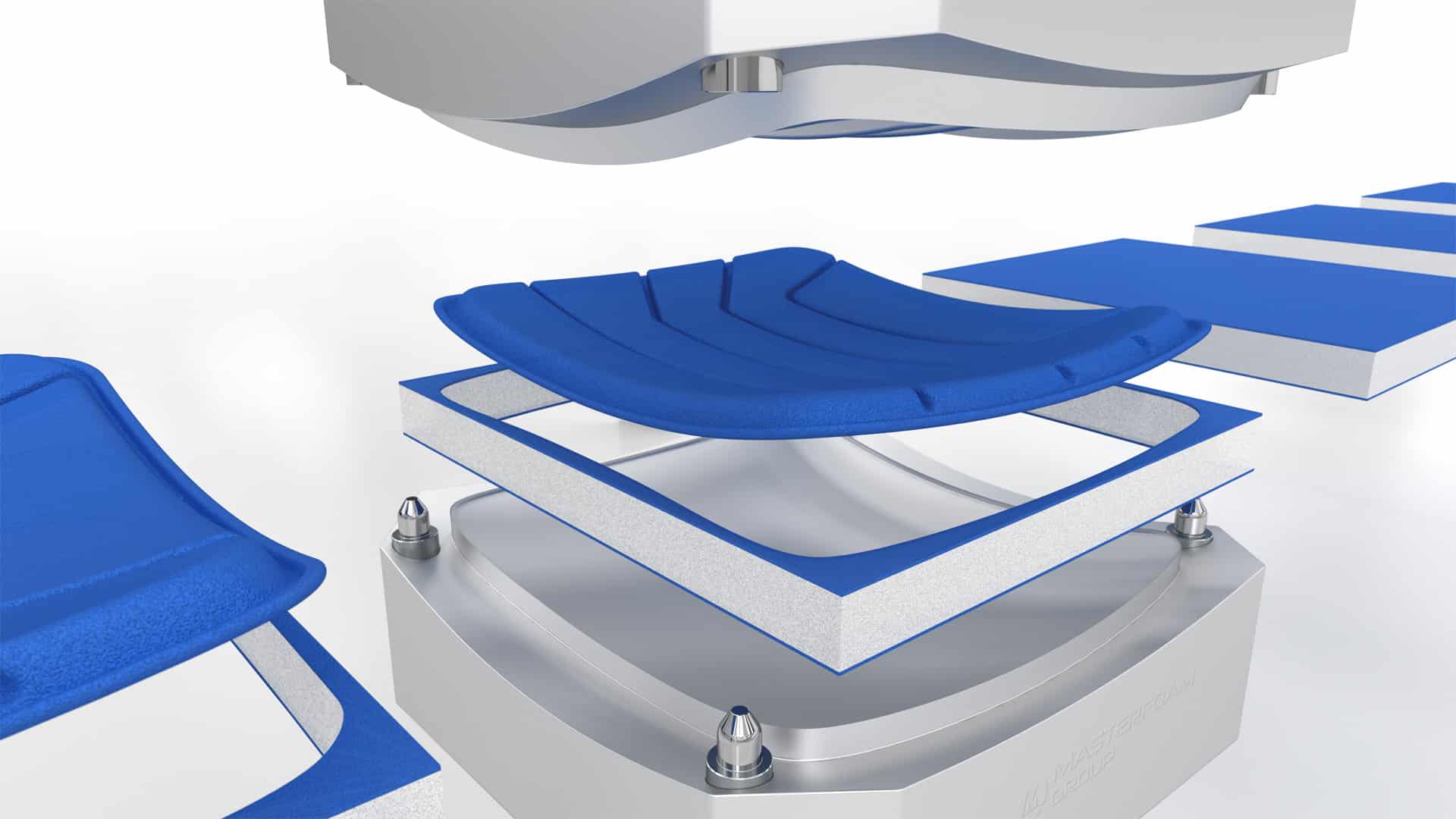

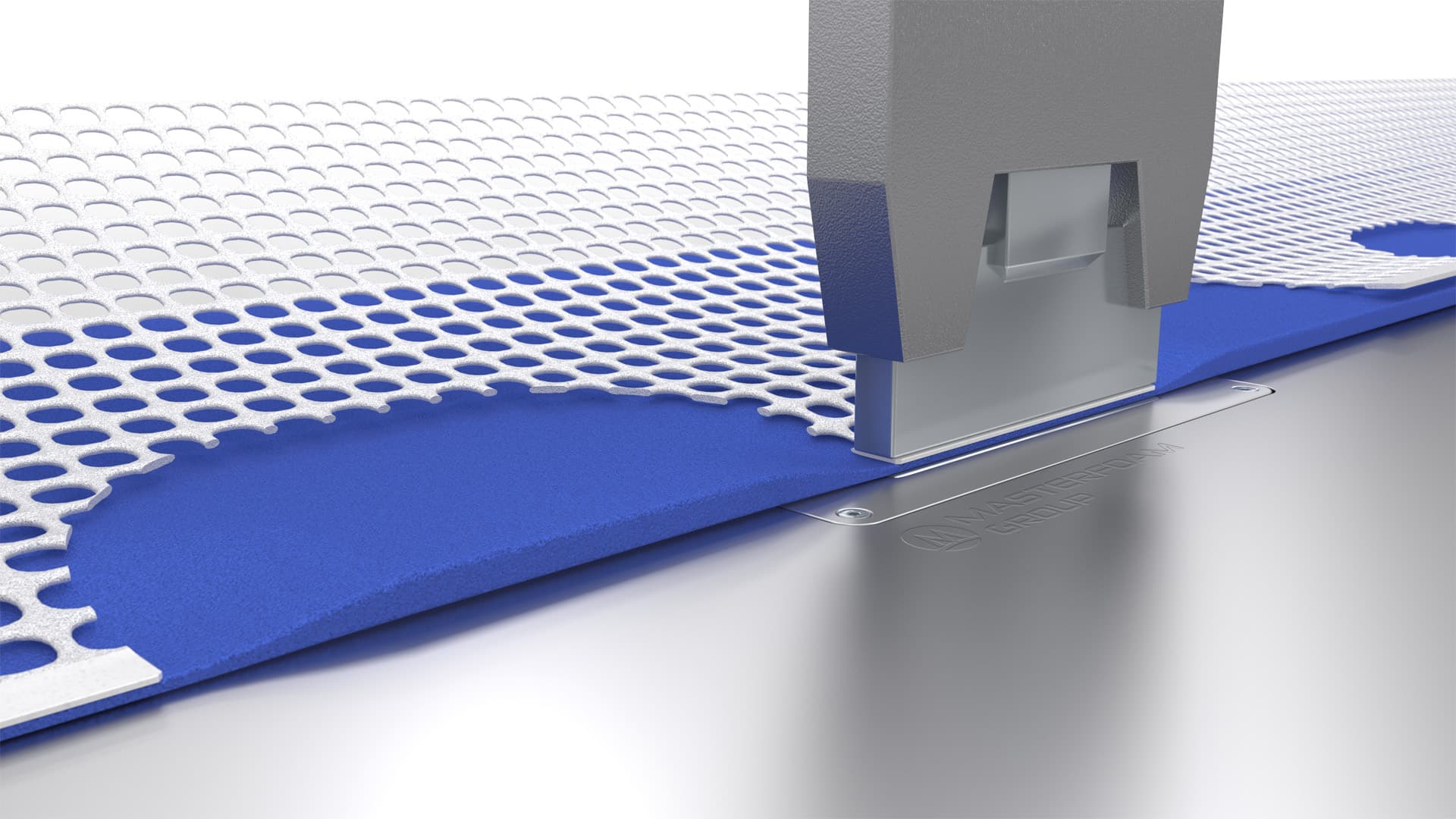

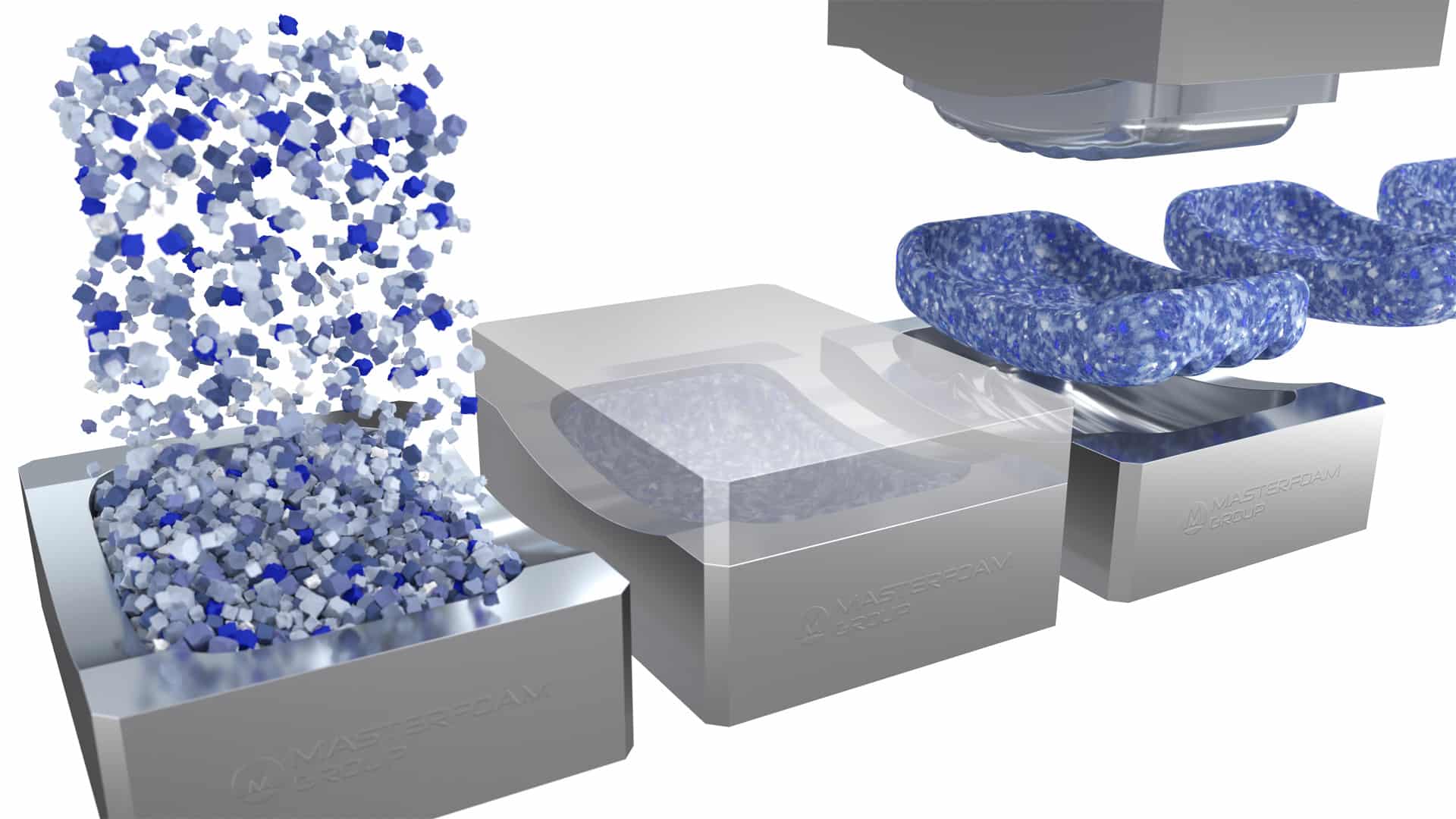

Ultrasonic Cut & Seal

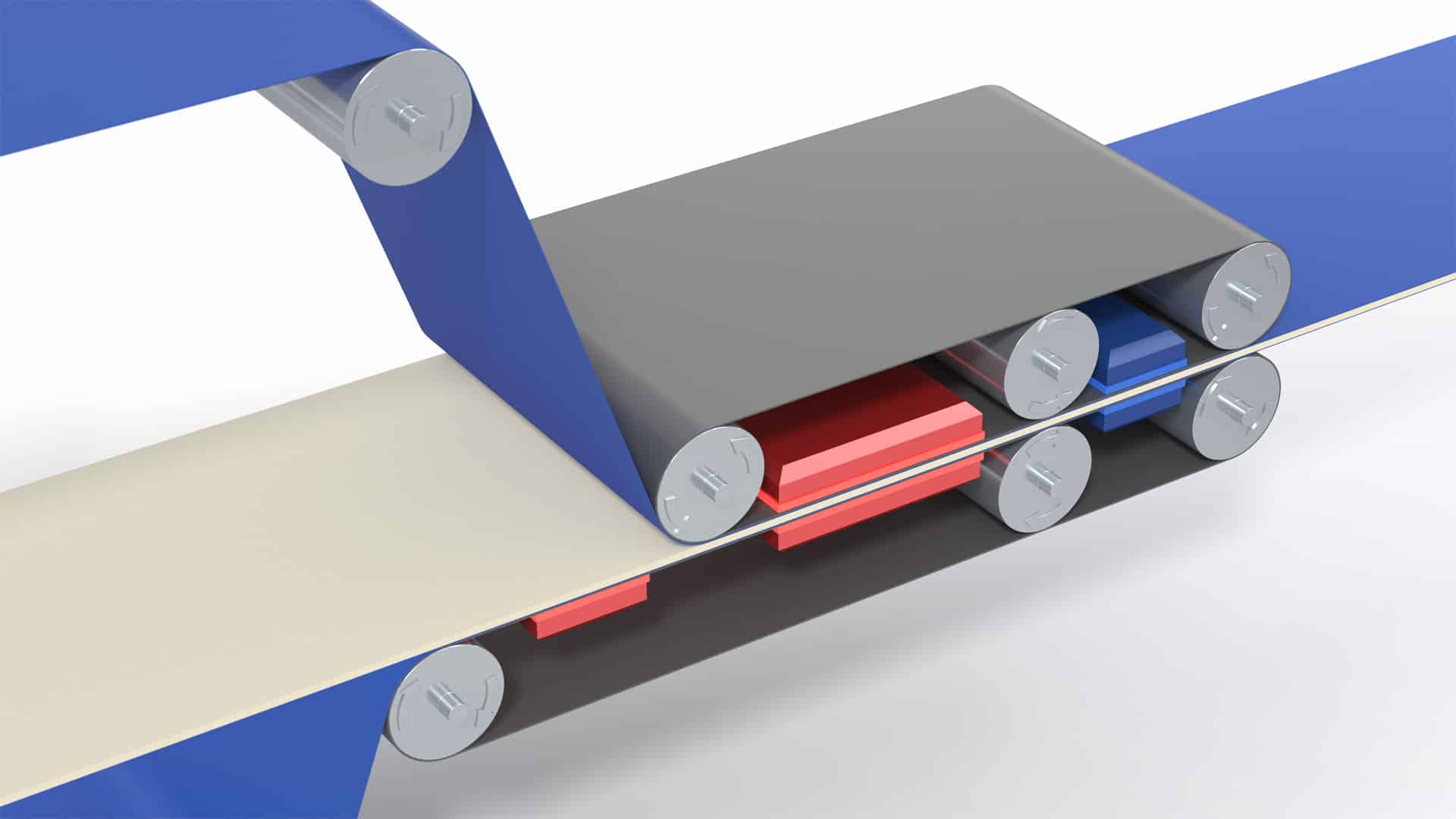

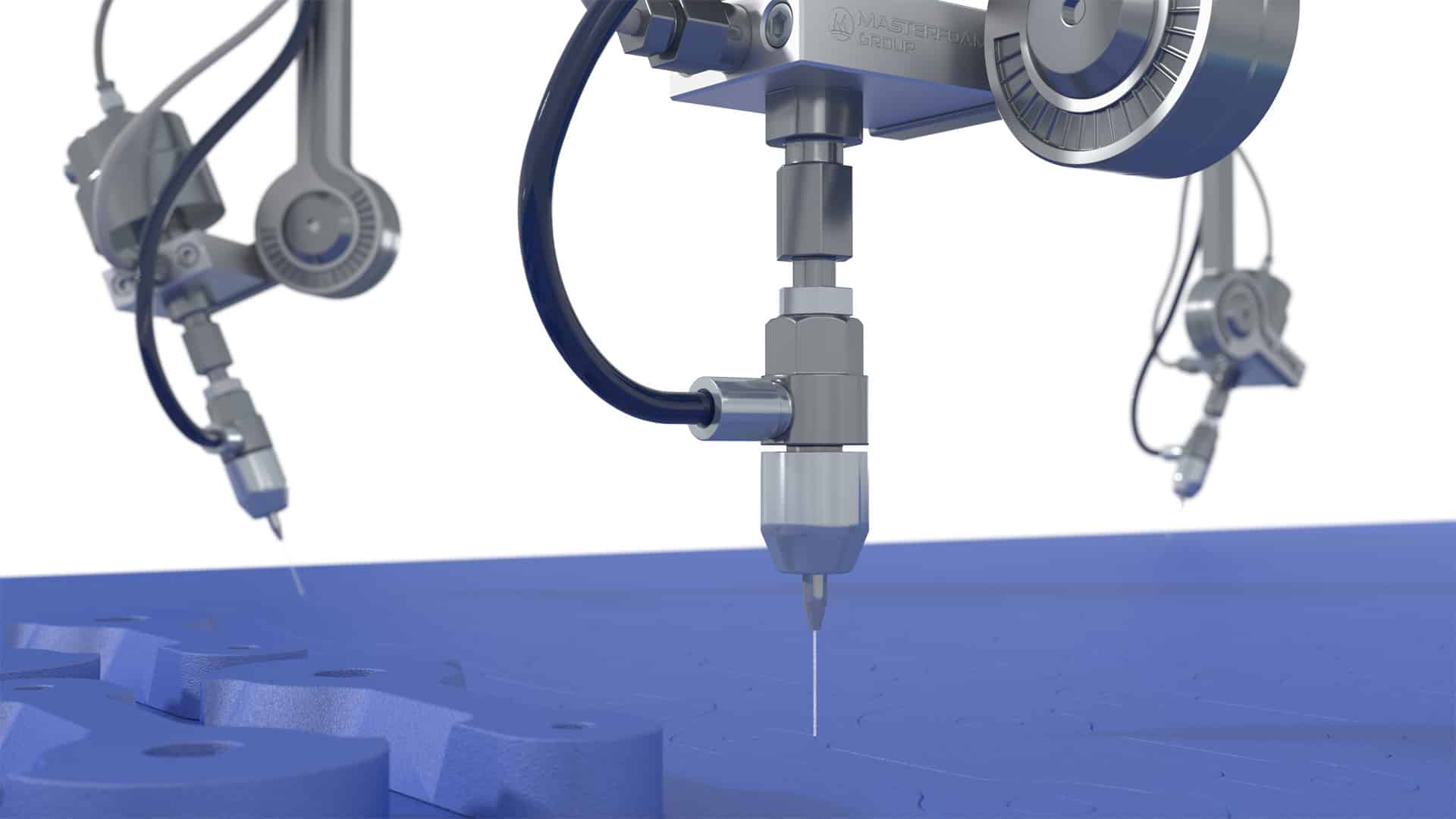

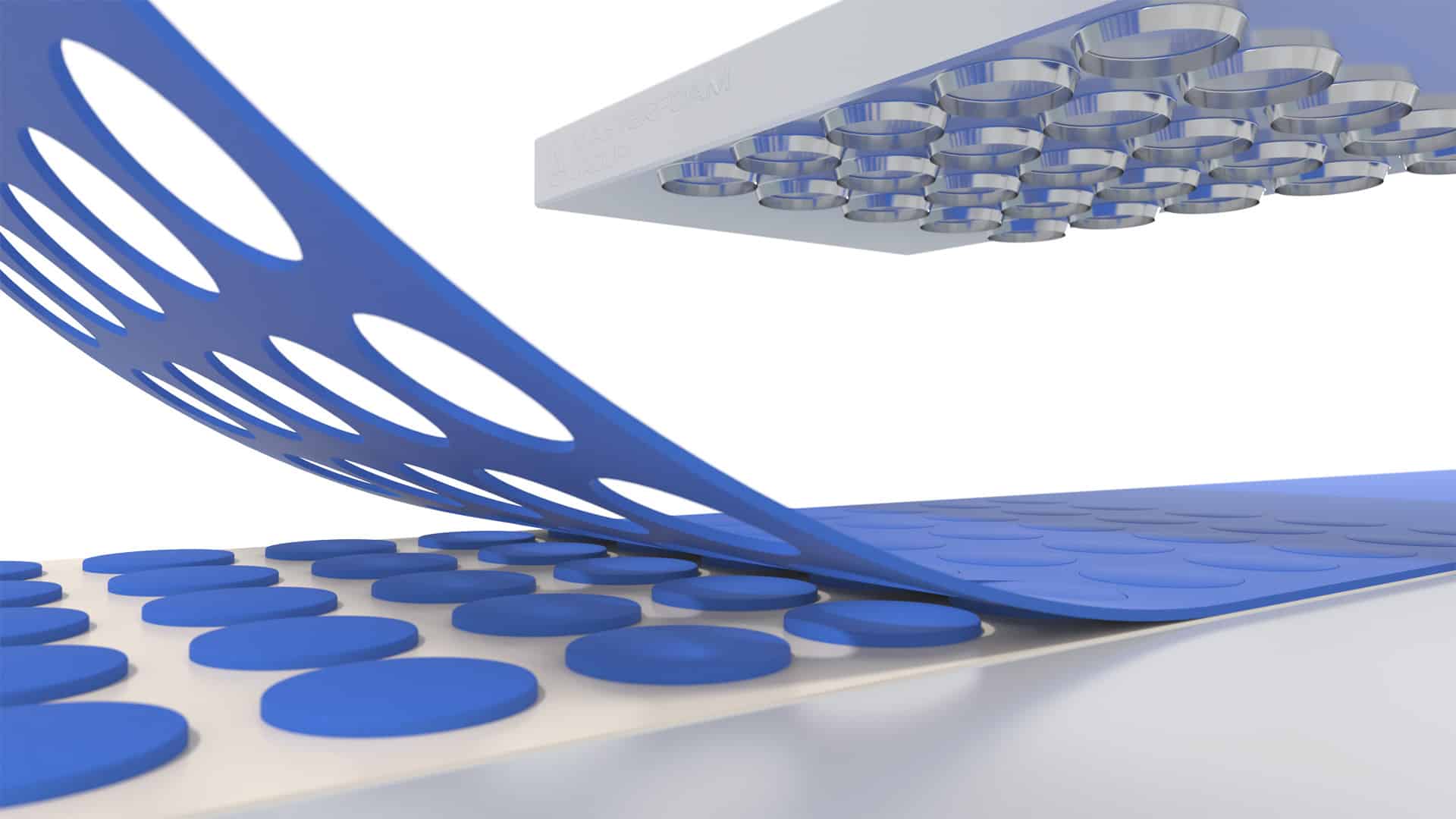

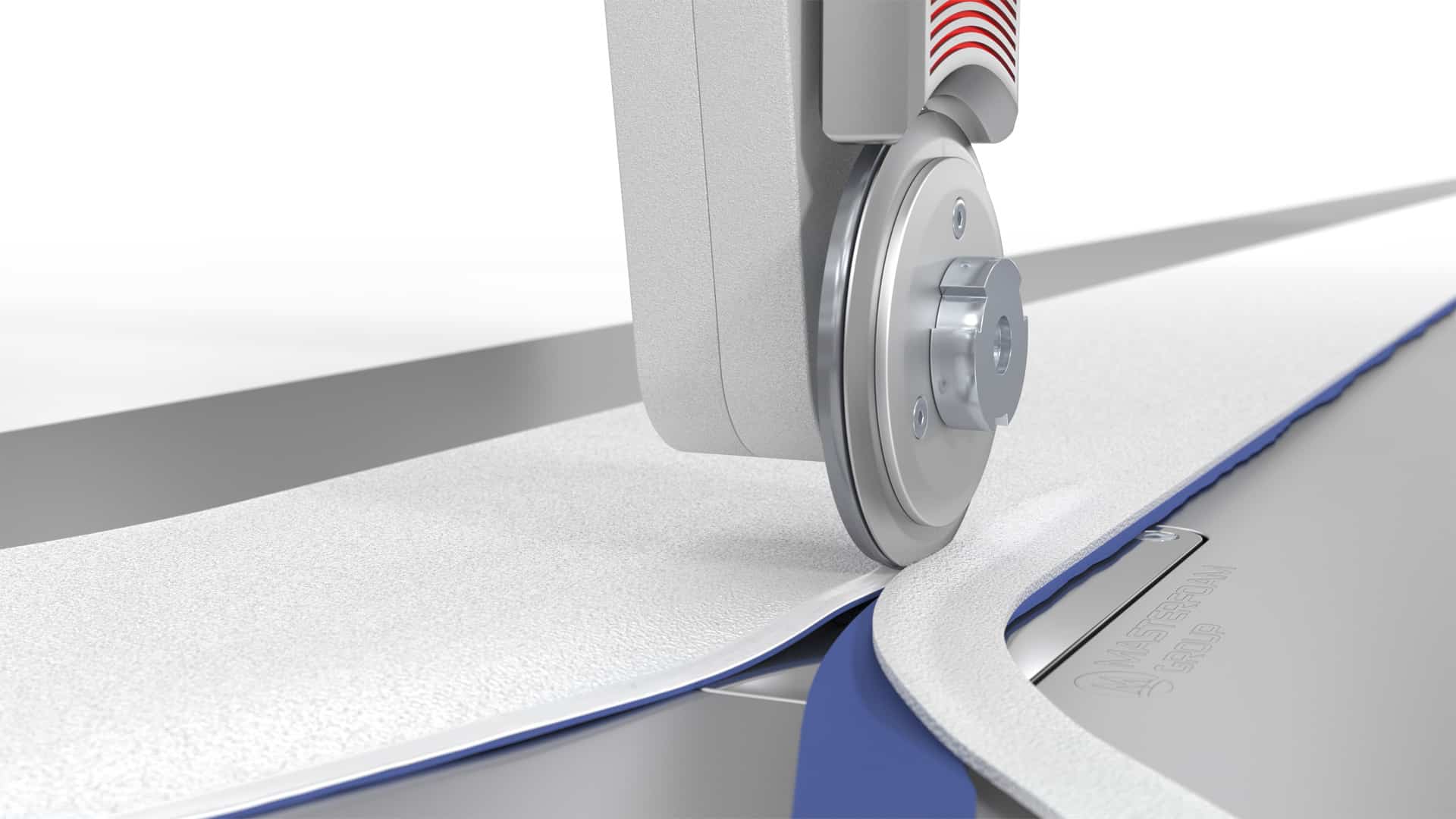

The ultrasonic Cut&Seal process is an industrial process whereby high-frequency ultrasonic acoustic vibrations are locally applied to workpieces being held together under pressure to create a solid-state weld. In ultrasonic welding, there are no connective bolts, nails, soldering materials, or adhesives necessary to bind the materials together. The process is used to seal edges as they are being cut or in order to make a process more efficient by combining the two steps.

Benefits

- Rapid welding cycles

- Inexpensive tooling

- Clean process

- No subsequent drying/hardening

- Strong bond