High Frequency Welding

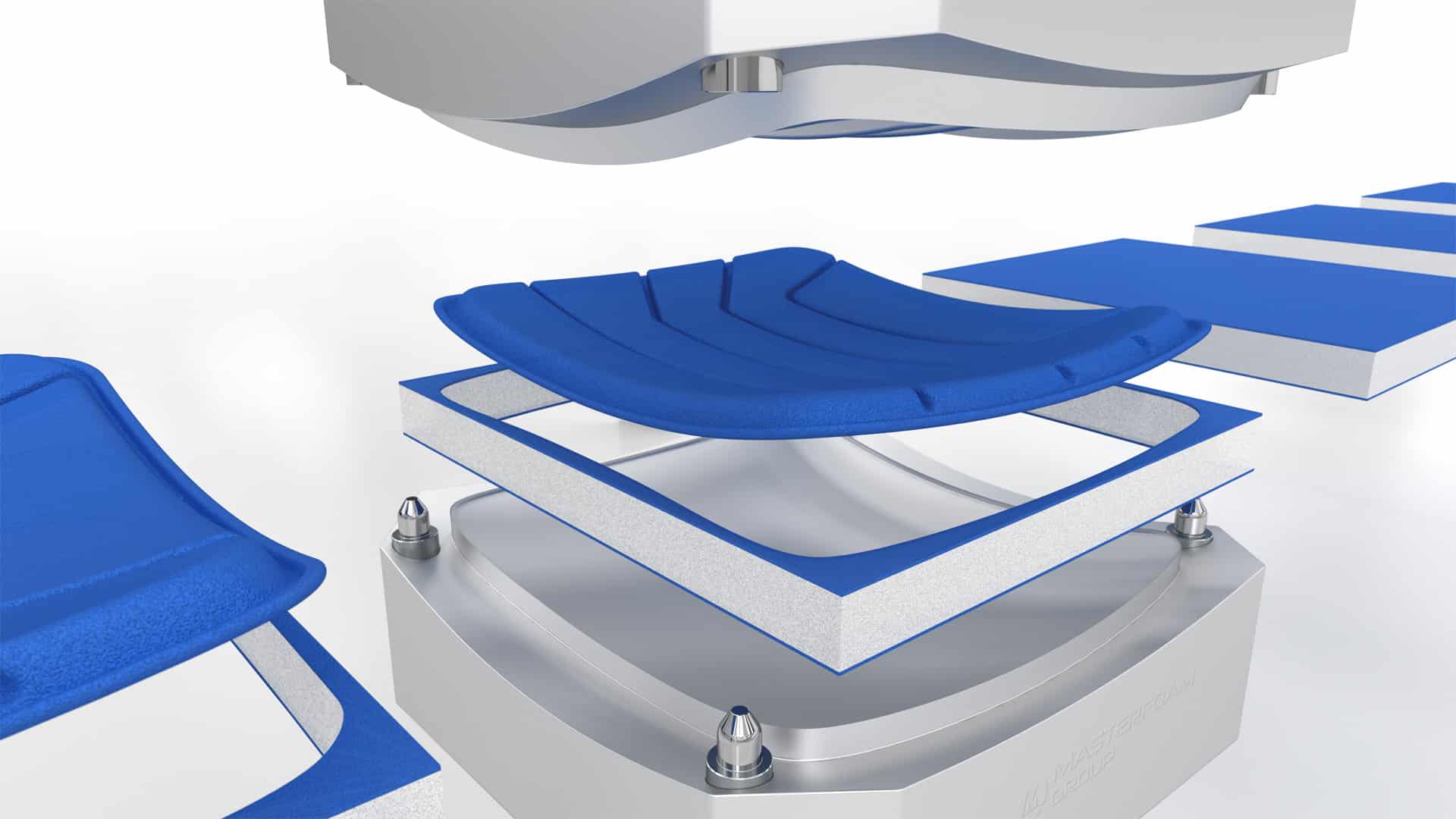

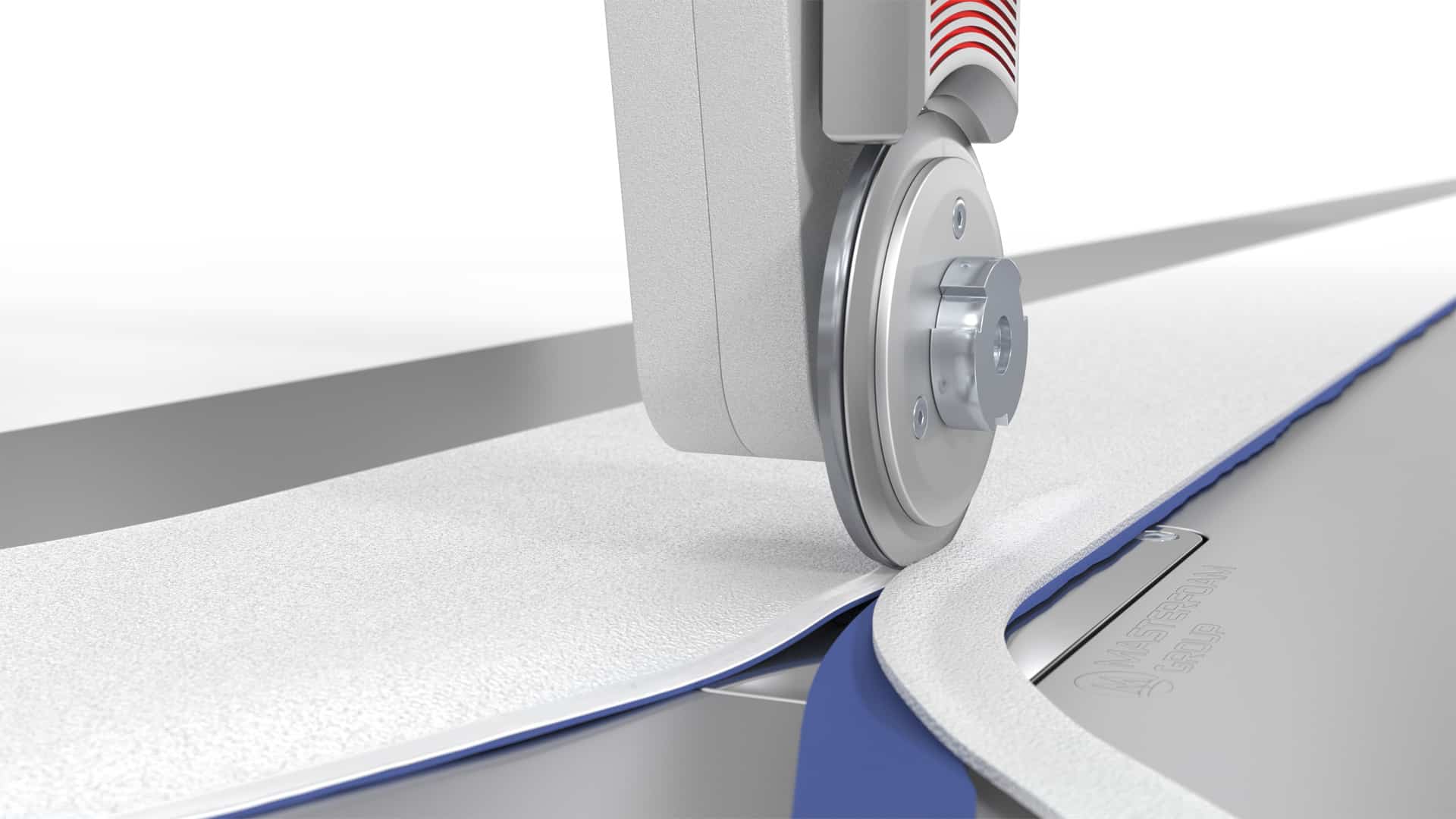

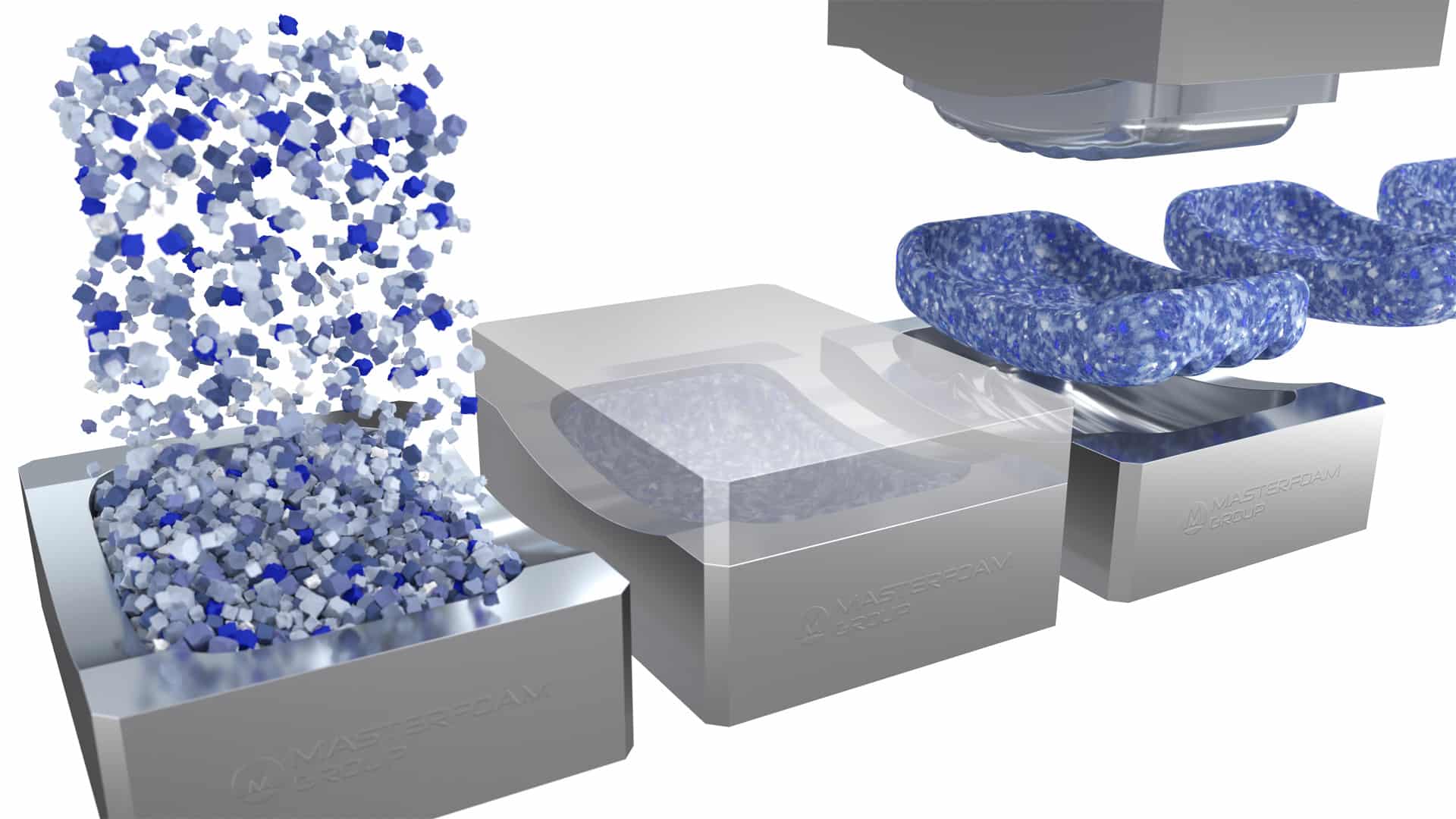

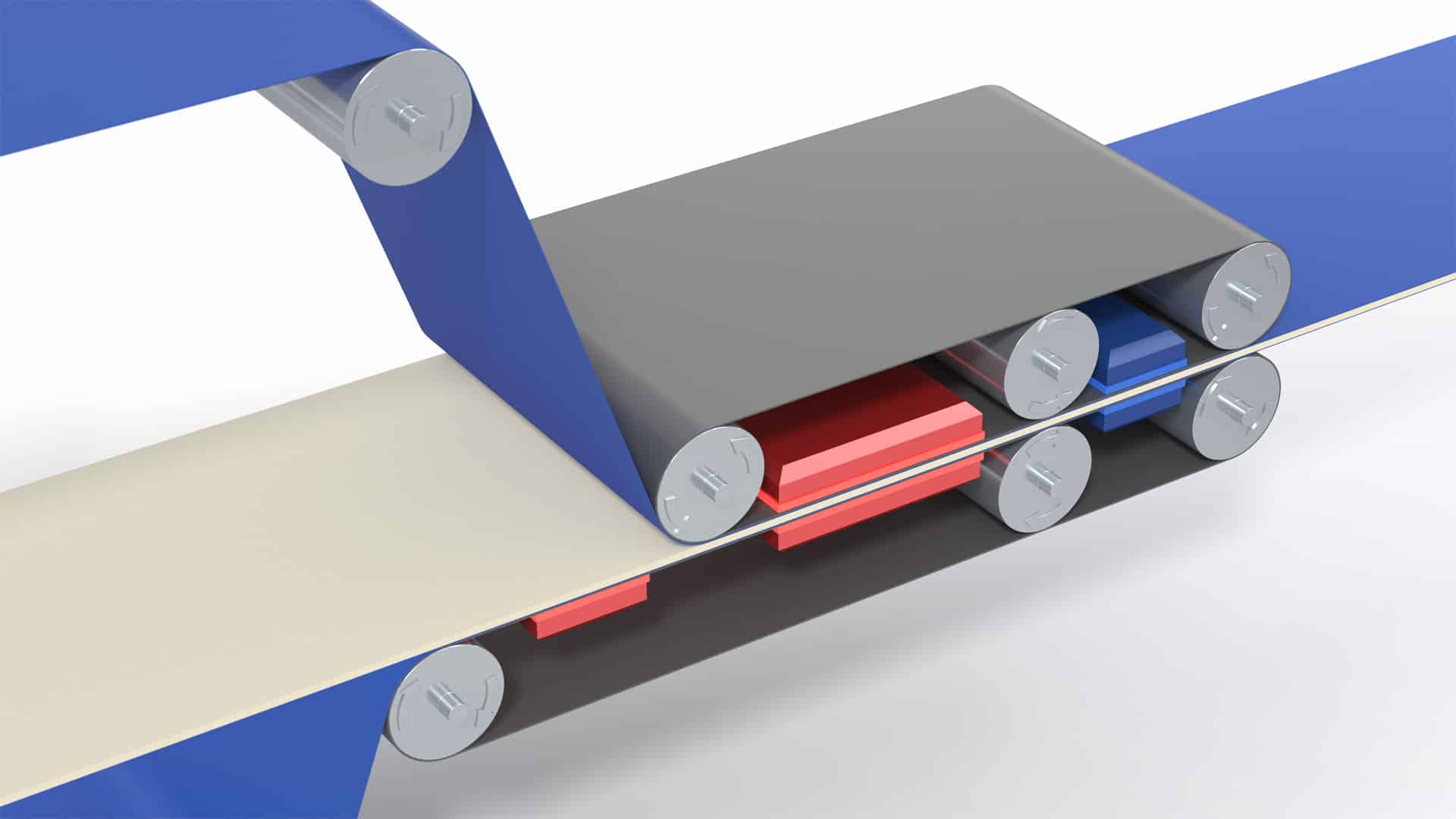

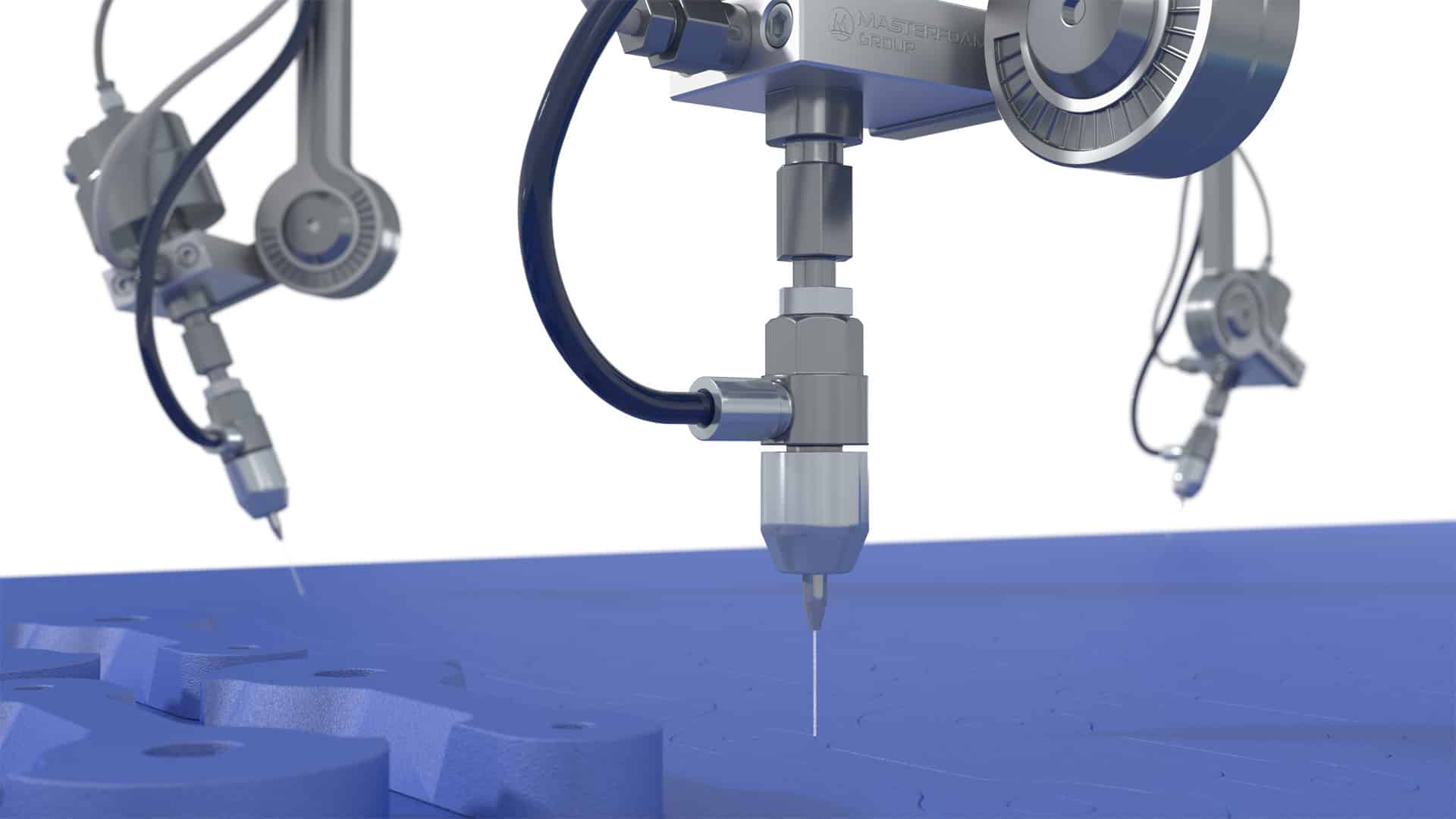

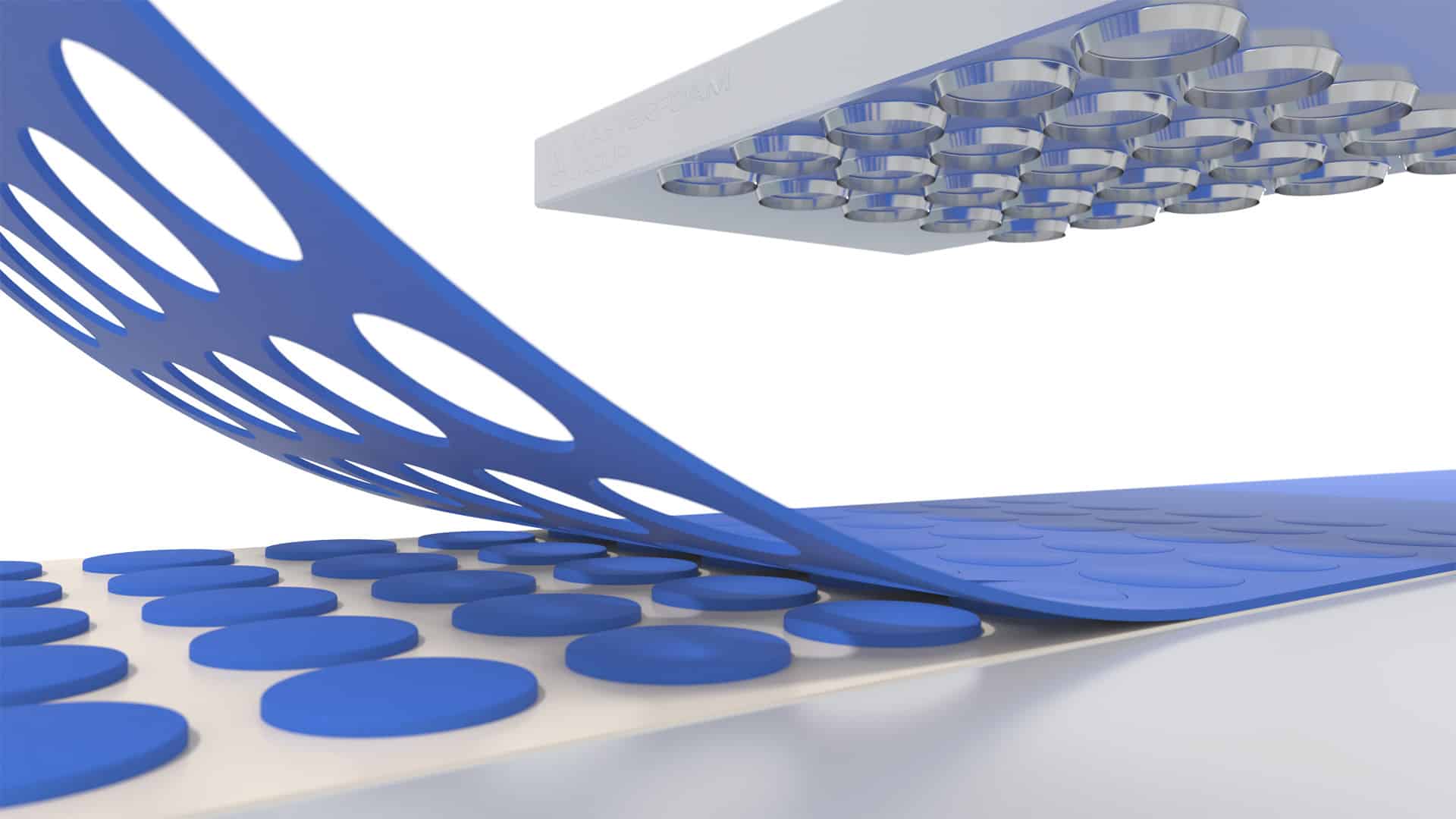

High Frequency welding, electromagnetic waves in the range of radio frequencies can heat certain polymers up to soften the plastics for joining. Heated plastics under pressure weld together. Heat is generated within the polymer by the rapid reorientation of some chemical dipoles of the polymer, which means that the heating can be localized, and the process can be continuous.

Benefits

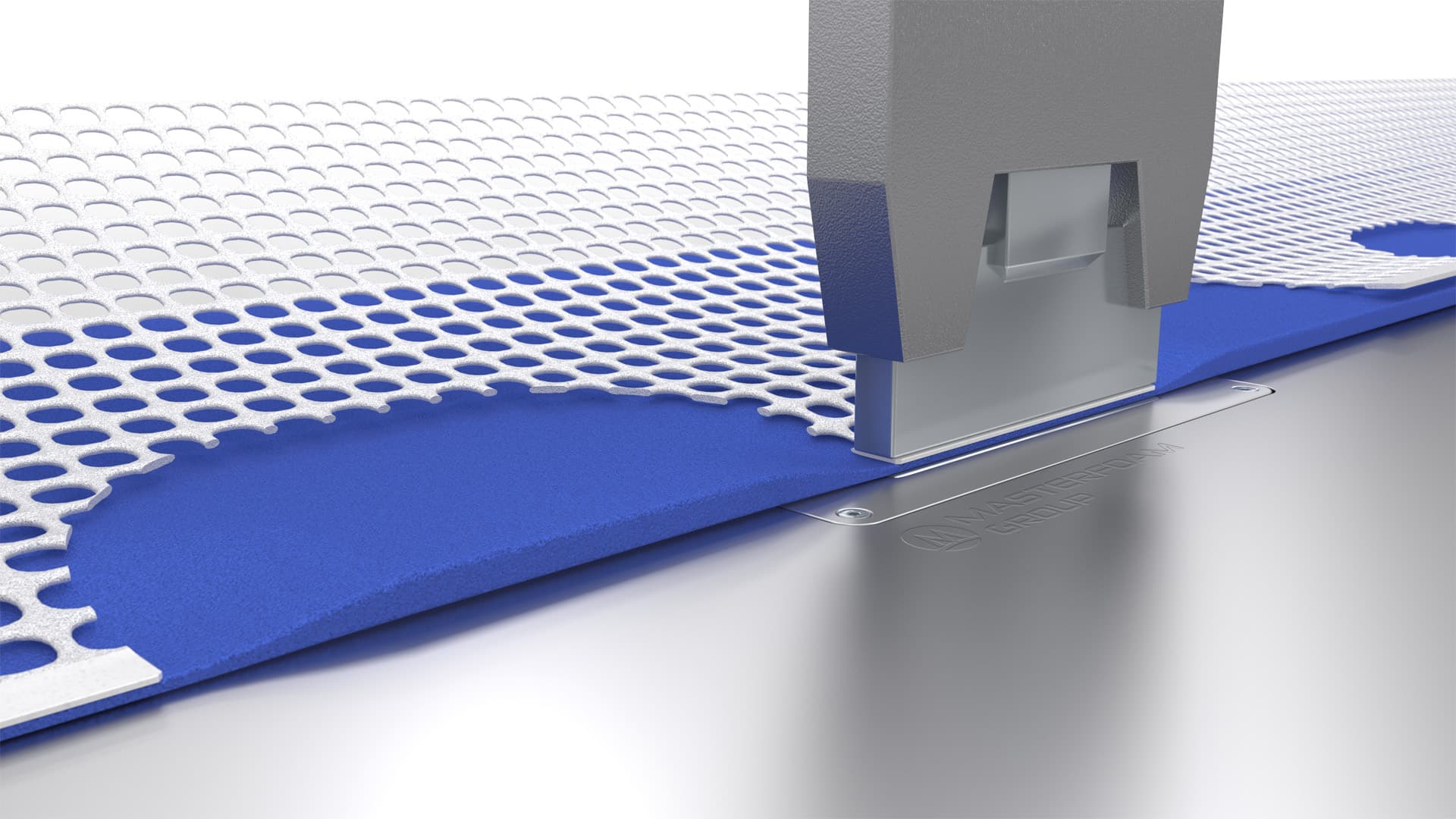

- Rapid welding cycles

- Inexpensive tooling

- Clean process

- No subsequent drying/hardening

- Strong bond