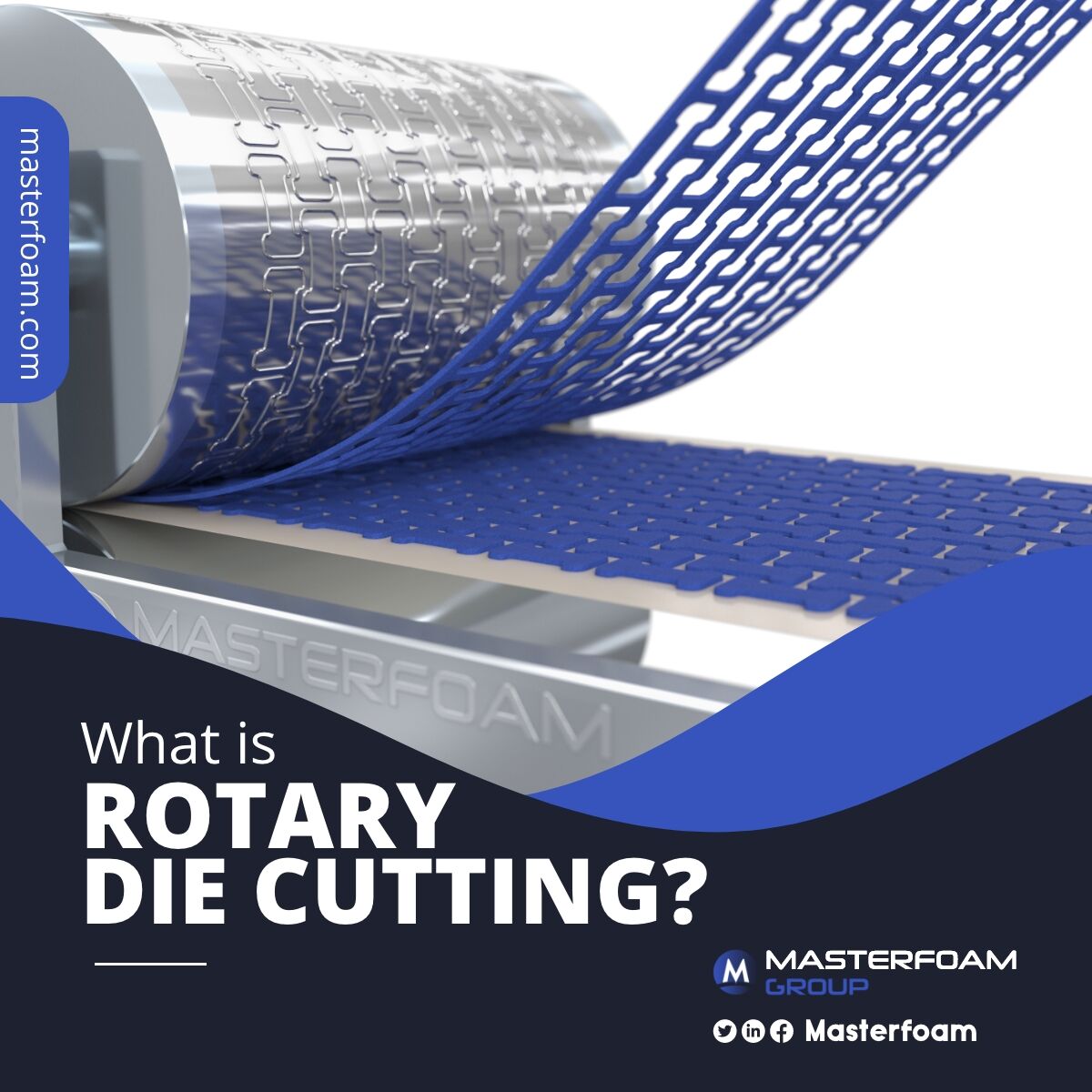

At Masterfoam, we use many different technologies to meet your individual customer needs. Today, once again, we would like to introduce you to one of these production processes. Now in focus: Rotary die cutting.

✅ The process can quickly produce large quantities, making it cost-effective for high-volume production runs.

✅ Rotary cutting can be used on a wide range of materials for different purposes.

✅ The rotary die cutting technology offers high precision, capable of producing complex shapes with tight tolerances.

✅ Dies can be customized to create products with intricate designs and patterns.

✅ In the cutting process, the group parts closely on the sheet, reducing waste.